How to Choose High-Speed Board-to-Board & Backplane Connectors: Complete Guide for 2024

2024-11-22

Blog

Richmon

Quick Selection Guide: High-Speed Connector Specifications

| Speed Class | Recommended Type | Key Specifications | Typical Applications | Cost-Performance Ratio |

|---|---|---|---|---|

| Basic (Up to 28 Gbps) | Standard PCIe | – Insertion loss: -3dB max – Crosstalk: -40dB min – Impedance: 100Ω ±10% | Enterprise servers, Storage systems | Cost-effective |

| Advanced (28-56 Gbps) | High-Performance PCIe | – Insertion loss: -2dB max – Crosstalk: -50dB min – Impedance: 100Ω ±5% | Data centers, High-end computing | Moderate |

| Premium (56+ Gbps) | Advanced Backplane | – Insertion loss: -1dB max – Crosstalk: -60dB min – Impedance: 100Ω ±3% | Telecommunications, AI/ML systems | Premium |

Table of Contents

Understanding Your Requirements

The global backplane market has reached an unprecedented $15 billion in 2023, according to MarketsandMarkets. This remarkable growth reflects the increasing demands of modern electronic systems, particularly in data centers and telecommunications infrastructure.

Market Dynamics Influencing Connector Selection

- Data Center Evolution: The shift toward higher data processing speeds requires connectors supporting 56 Gbps and beyond.

- 5G Infrastructure: Telecommunications equipment demands ultra-high-speed backplane solutions.

- AI/ML Applications: Artificial intelligence and machine learning systems need superior signal integrity.

- Edge Computing: Distributed computing architectures require reliable high-speed connections.

Critical Requirements Analysis

Before selecting a high-speed connector, consider these essential factors in your system design:

Data Speed Requirements

- Current data rate needs

- Future bandwidth projections

- Protocol compatibility (PCIe, Ethernet, etc.)

- Latency requirements

Physical Constraints

- Board space availability

- Mounting requirements

- Airflow considerations

- Component clearance needs

Environmental Considerations

- Operating temperature range

- Humidity tolerance

- Shock and vibration resistance

- Industrial grade requirements

Critical Selection Factors

Selecting the right high-speed connector requires careful consideration of multiple technical parameters. Our server applications guide provides detailed insights into these critical factors.

Signal Integrity Specifications

Insertion Loss

- Optimal: < -1dB at Nyquist frequency

- Acceptable: < -3dB at Nyquist frequency

- Impact: Direct effect on signal quality

- Measurement: Vector Network Analyzer (VNA)

Return Loss

- Optimal: < -20dB across frequency range

- Acceptable: < -15dB across frequency range

- Impact: Signal reflection minimization

- Consideration: Impedance matching crucial

Crosstalk Performance

- Near-end (NEXT): < -60dB

- Far-end (FEXT): < -50dB

- Impact: Signal interference prevention

- Solution: Advanced shielding techniques

Types of High-Speed Connectors

Explore our comprehensive connector solutions designed for various high-speed applications.

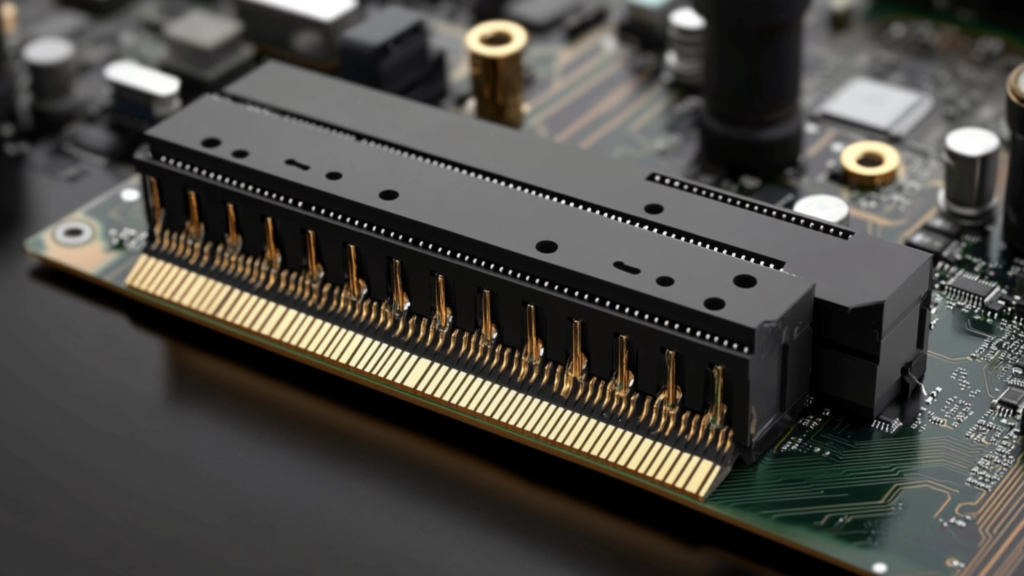

PCIe Connectors

- Gen 5.0 Capabilities:

- Data rates up to 32 GT/s

- Enhanced signal integrity

- Backward compatibility

- Optimized power delivery

- Applications:

- Server systems

- Storage arrays

- Graphics processing

- AI accelerators

Backplane Connectors

- High-Speed Features:

- 112+ Gbps capability

- Dense pin configurations

- Superior EMI shielding

- Robust mechanical design

- Best For:

- Telecommunications

- Data center infrastructure

- Industrial automation

- Network switches

Common Challenges and Solutions

According to Electronic Design, signal integrity issues remain one of the primary challenges in high-speed connector applications. Here’s a comprehensive guide to addressing these challenges:

Signal Integrity Issues

Challenges:

- Signal degradation at high frequencies

- EMI susceptibility

- Impedance mismatches

Solutions:

- Advanced shielding techniques

- Optimized pin assignments

- Controlled impedance design

Thermal Management

Challenges:

- Heat dissipation in dense designs

- Temperature-related performance drift

- Material limitations

Solutions:

- Enhanced airflow designs

- Advanced thermal materials

- Optimized power distribution

Testing and Validation

According to EDN Network, comprehensive testing is crucial for ensuring reliable high-speed connector performance. Here’s a detailed testing framework based on industry standards:

Essential Testing Parameters

Electrical Testing

- Signal Integrity:

- Eye diagram analysis

- S-parameter measurements

- Impedance profiling

- Crosstalk evaluation

- Power Integrity:

- Current carrying capacity

- Voltage drop measurement

- Power distribution analysis

Mechanical Testing

- Durability:

- Mating cycles: 250+ minimum

- Contact resistance stability

- Insertion/extraction force

- Environmental:

- Temperature cycling

- Humidity resistance

- Shock and vibration

Future-Proofing Your Selection

The connector industry continues to evolve rapidly. Based on research from Grand View Research, here are key trends shaping the future of high-speed connectors:

Emerging Technologies and Trends

Speed Evolution

- 112 Gbps PAM4 becoming standard

- 224 Gbps on the horizon

- Advanced signal processing integration

Design Innovations

- Miniaturization advances

- Novel material developments

- Integrated cooling solutions

Industry Requirements

- Enhanced power efficiency

- Improved thermal management

- Greater design flexibility

Making Your Final Decision

Comprehensive Selection Checklist

| Factor | Considerations | Priority Level |

|---|---|---|

| Performance Requirements |

| Critical |

| Physical Constraints |

| High |

| Cost Considerations |

| Medium |

Ready to Optimize Your High-Speed Connectivity?

Trust Richmon’s expertise in high-speed connector solutions. Our engineering team is ready to help you:

- Select the optimal connector for your application

- Ensure compliance with industry standards

- Maximize system performance

- Reduce implementation challenges

Want to Get Quality Connectors from Reliable Original Factory Channel ?

An professional sales engineer will help you on connector selection, get best quotes, support you all the way until products arriving your office.